HydroSelf Round

The Challenge

Most flushing systems available on the market for circular and small rectangular tanks are uneconomical in comparison with the construction costs. These tanks have to be cleaned manually especially when there is no electric power at hand. Circulation power units, which can only be powered electrically, counteract the sedimentation process, for which the tank is designed.

The Solution

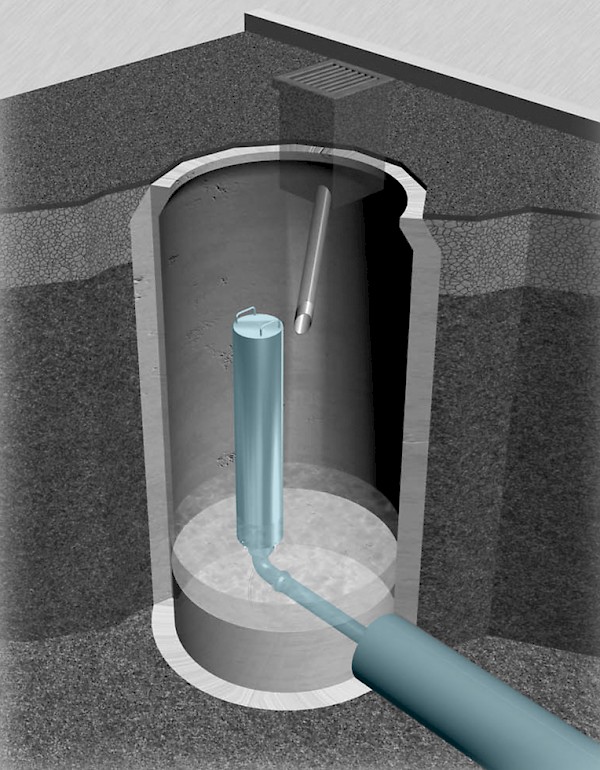

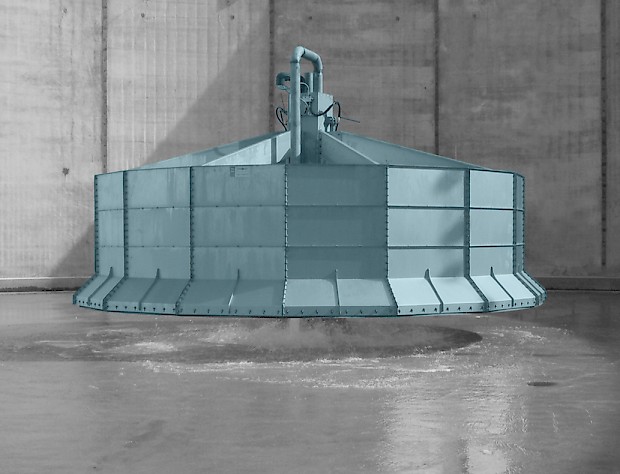

The HydroSelf for circular and small rectangular tanks is a container flush. It is placed on a base plate with central guide rod, to which the container guide and the closure are positioned. The circular or rectangular outer wall is at the same time the storage reservoir separating wall. The filling occurs by means of a backwater gate near the ground or above the overspill crest of the container itself. After impounding, the detained combined water is situated in the flush container. The container separating wall, sloping in the lower part, receives impetus from the water in the flushing container. When the closure in the container is opened by means of float technology or ultrasonic detector, then the whole container wall is raised and a radial flush wave occurs.

The Functional Principle

- Phase I – Dry weather

The dry weather effluent flows into the tank and then further over the radial dry weather flume, which is also the flushing sump, towards the outflow.

- Phase II – Stormwater

By stormwater the circular tank is filled from the outflow, i.e. first the flushing sump. The float rises and shuts the closure mechanism of the container. By further stormwater, the flushing container is filled via the backwater gate proportionate to the water level in the container. Even with partial filling there is enough flushing water in the container. By means of a pre-throttle, flushing water can flow into the flushing container before the flushing street is wetted.

- Phase III – after stormwater

After a stormwater event the tank empties. The flushing water is retained in the flushing container. Because of the sloping wall, impetus is created. When the flushing sump is emptied, the float sinks and unlocks the closure.

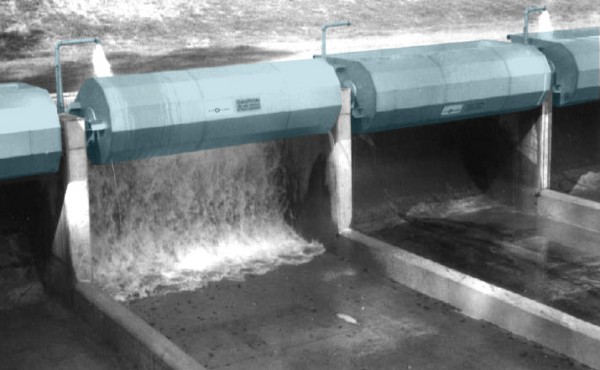

- Phase IV – Flushing

The power which is created by the impetus against the sloping container wall, raises the whole container upwards. A flush wave pours over the whole tank bottom and flushes deposits into the flushing sump.

The Advantages

- Very favourable cost effectiveness

- Automatic filling, even with partial inflow

- Float technology with no external power, therefore no operational costs

- Optimal cleaning results even with heavier deposits

- Can be retrofitted

- No additional construction technology

- Durable

- Manual flushing

- Flexible adjustment

- Optional: electro-hydraulic control

Top of page